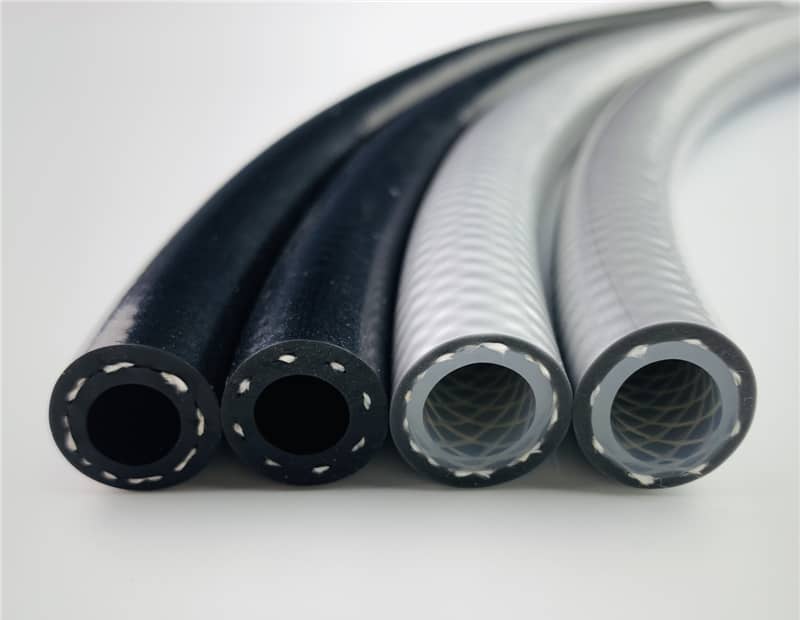

High-frequency equipment braided silicone tubes are made of silica gel as the base material and then woven with fiber threads. The molding process is particularly complicated, including two extrusion processes and one weaving process. At the same time, two different equipments are required to work completely. The braided silicone tube for high-frequency equipment should be kept clean as much as possible during the production process, because after the inner tube of the braided silicone tube for high-frequency equipment is extruded, it will absorb dust in the air, and the weaving process is machine-woven, and it is easy to wrap the dust together, which will As a result, the braided silicone tube of the high-frequency equipment in the later stage will be inflated when it is subjected to high-intensity air pressure during work, and the dust has been wrapped, which will also lead to uneven force and directly cause the air pressure to gushe out from here, displacing the high-frequency equipment The surface of the braided silicone tube breaks down, so it cannot be ignored because of a small dust. A high-frequency equipment braided silicone tube product usually has big problems that are easy to solve, and it is often the details that determine the quality of the product .