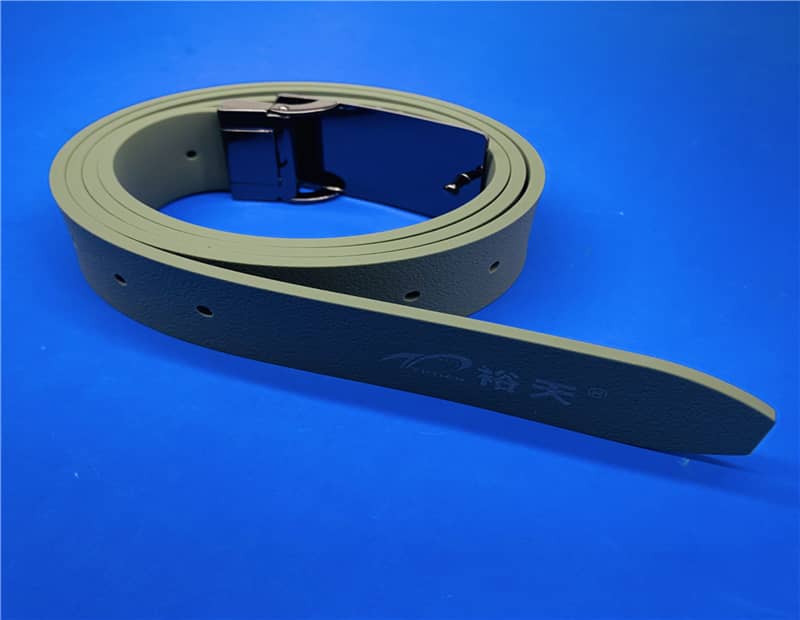

The production process of silicone belt is more complicated and more practical to use. It is necessary to choose high-life tear-resistant materials to prevent the silicone belt from being damaged when punching holes, and as a daily necessities, it needs to be used for a long time, so the selected raw materials are made of high-end materials. , to ensure that the product is not prone to breakage or a series of sequelae such as a short service life in daily use. The silicone belt is made by the silicone calendering process, and it needs to be punched according to the required size and specifications. It is made on the surface of a large silicone sheet according to the specifications required by the customer, and this silicone sheet is the predecessor of the silicone belt. Because of the use of the silicone belt. Two surface effects (in order to distinguish the front and back sides) In addition, the surface of the silicone belt generally needs to be sprayed to avoid absorbing dust in the air. This is adopted so that it does not attract dust. The other is that the punching process is made of tear-resistant material, even if there are burrs in the punching, it will not easily affect the use effect of the silicone belt.