0086-769-82555312

0086-18046921526

0086-13826958536

0086-18046921526

0086-13826958536

- Home

- About Yutian

-

Product

- Silicone tube

- Preferred silicone hose

- Silicone corrugated pipe

- Peristaltic pump silicone hose

- Silicone straw

- Silicone braided tube

- Communication/power shrink tubing

- Foamed silicone hose

- Silicone sealing strip

- LED light strip silicone sleeve

- Silicone rubber sealing ring

- Bicycle handle cover/strap

- Industrial special silicone rubber products

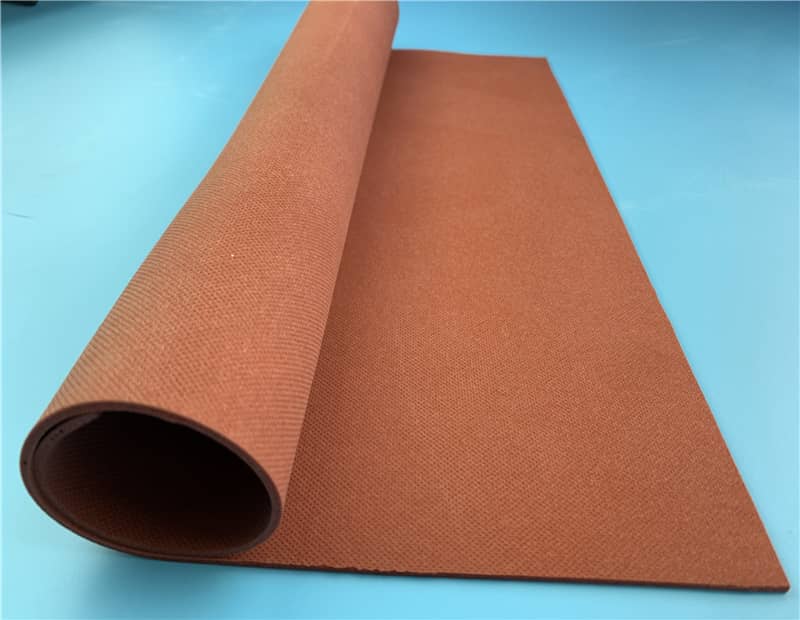

- Silicone sheets and miscellaneous parts

- Application

- News

- Contact