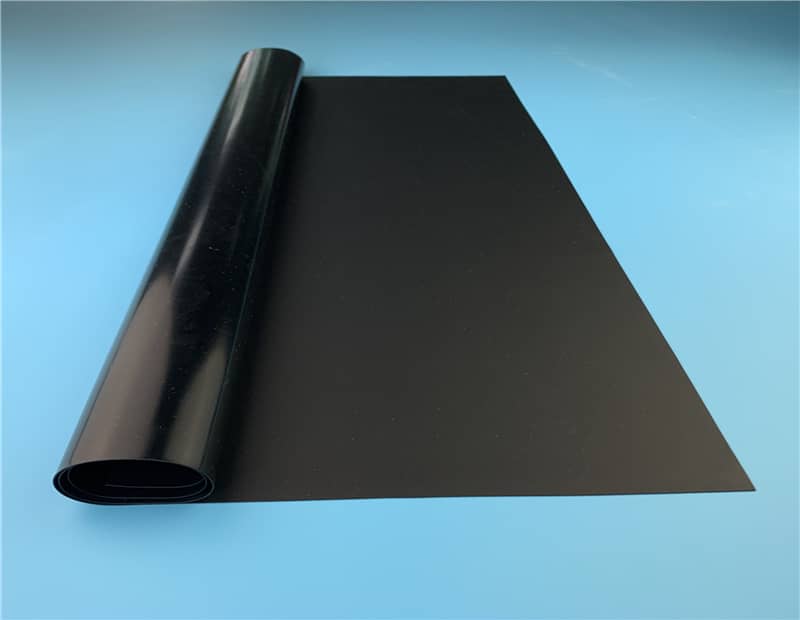

The anti-static silicone sheet is produced by calendering process and post-processing to achieve anti-static effect. The principle is that after the silicone sheet is produced, oil is sprayed on demand. For example, A side needs to be anti-static and B side does not need anti-static, so the oil injection treatment needs to be done on A side. Spray to meet anti-static requirements. The standard size of the product before die-cutting is 50°, and the width is 500mm. Generally, it is calculated according to the square. If the customer needs to make non-standard customization, it needs to be calculated separately. If it is a die-cutting process, it needs to be opened. The mold is simple The extent depends on customer requirements. The hardness of the silicone sheet is not much different from that of the silicone tube, but the special hardness (such as 75° or 10~30° low hardness) will affect the unit price of the silicone sheet, while the unit price of the silicone tube is not affected by the hardness. This is The difference between the two. In addition, it can produce products with foaming and calendering technology, such as mesh grids and straight grids, which are not prone to yellowing, embrittlement, and cracks after long-term use, and meet multiple testing requirements.