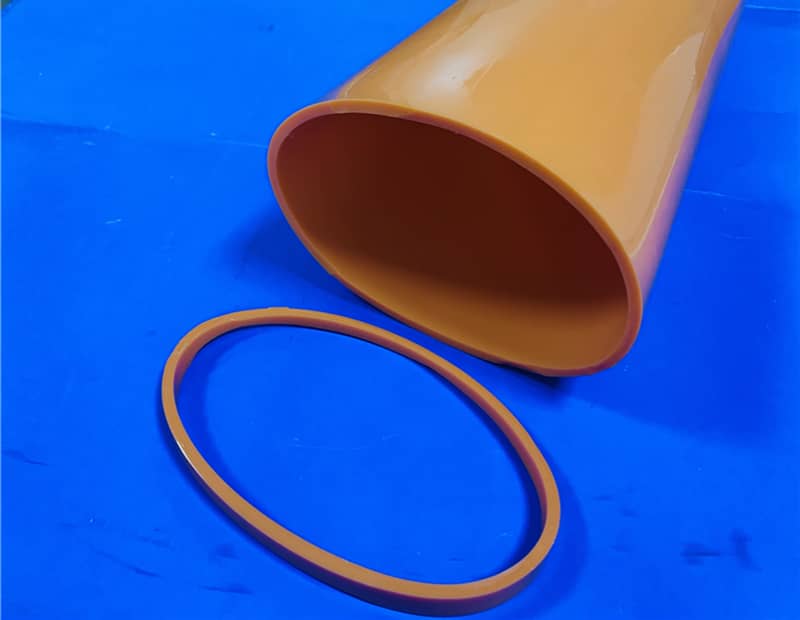

The main feature of the corona machine silicone tube is high temperature resistance and fatigue resistance test. From the perspective of production, its size is too large. Generally, it needs to be in the size range of 100~250mm, so these two indicators have been limited . There are many silicone tube extrusion manufacturers. The problem of the size of the corona machine silicone tube is that it needs to be manufactured by a large-scale extrusion vertical machine, and the stock of this kind of equipment in the market is relatively small, so most companies cannot manufacture it. Dongguan Yutian relies on New technology and new machines can currently realize long-term orders for corona machine silicone tubes with a size below 250mm. The raw materials of the corona machine silicone tube are divided into ordinary materials and high-temperature-resistant special materials. If the rollers work for a long time, the roller will continue to generate high-temperature power generation. At this time, the corona machine silicone tube is needed to play the role of heat insulation and power generation. It can withstand the temperature below 200° and cannot be exposed to the temperature above 200° for a long time. If the corona machine used by the customer does not work for a long time, the silicone tube of the corona machine with ordinary glue can be used. Otherwise, it needs to be made of high temperature resistant special materials. On the premise of these two core indicators, many enterprises have been stumped. In addition, the roller of the corona machine is large in size and the silicone tube needs to be covered on its surface to play the role of power generation and heat insulation. If the silicone tube is to be covered It needs to be expanded to go up. Generally, it needs to be enlarged by more than 1 times to cover the roller. After covering the roller, it needs to hug the roller tightly without loosening. This requires good shrinkage performance of the silicone.